Increase Plant Capacity in Food & Beverage Manufacturers

Reduce unplanned downtime, improve operations productivity, and reduce maintenance costs.

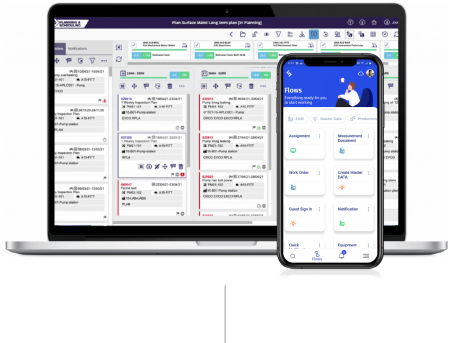

Sigga Simplifies the Digitization Process

A 2022 Survey in Food Processing found that the top operational challenges in the industry were workforce shortages (50%), skills gaps (54%), and unplanned downtime (46%). Outdated paper-based processes are intensifying these issues. Deploying mobility and work automation tools for SAP will save you time, money, and improve data capture, leading to less downtime and increased revenue.

Sigga enables food and beverage manufacturers to:

Increase OEE

Reduce unplanned downtime

Reduce MTTR

Increase technician productivity

Increase MTBF

Adherence to PM schedule

Improve Collaboration

Real-time visibility in SAP to resources and work status

Increase Staff Productivity

Reduce data entry and time wastes

Increase Compliance

Complete and documented safety inspections

Food and Beverage customer results

Here’s just some of the results our Food and Beverage clients achieved through end-to-end digital work management with Sigga.

Wrench Time

25%

Increase

Worker Productivity

15%

Increase

MTBF

10%

Increase

Sigga customers share their transformations

80% Reduction in MTTR in AB InBev bottling plants

Ambev, a part of Anheuser-Busch InBev, replaced a home-grown mobile maintenance app with Sigga’s and increased technician productivity by 21%. Download the Success Case to read the full story.

Deploying Mobility with 3000 Maintenance Technicians at BRF

See how a mobile EAM app, on a no-code platform, is rapidly transforming BRF, a global food company’s maintenance operation reducing costs, downtime, and increasing productivity.

Turning around a reactive maintenance environment at Ingredion

Planning and Scheduling went from 2 days to 2 hours. Technician wrench time increased by 25%. Hear how the Reliability Director and Sigga got these results at Ingredion, the 8th largest food ingredient company in the world.

Effective resolutions for operational challenges

Sigga understands your challenges and can guide you through a digital transformation across maintenance operations. More than 70,000 technicians across the globe use Sigga mobile maintenance app every day. And some of the world’s largest food & beverage organizations rely on Sigga Planning & Scheduling. Investing in digital maintenance tools now will help keep your organization profitable and competitive long-term.