Optimizing Uptime in Manufacturing Plants

Plant maintenance solutions for SAP® can materially reduce unplanned downtime and slowdowns.

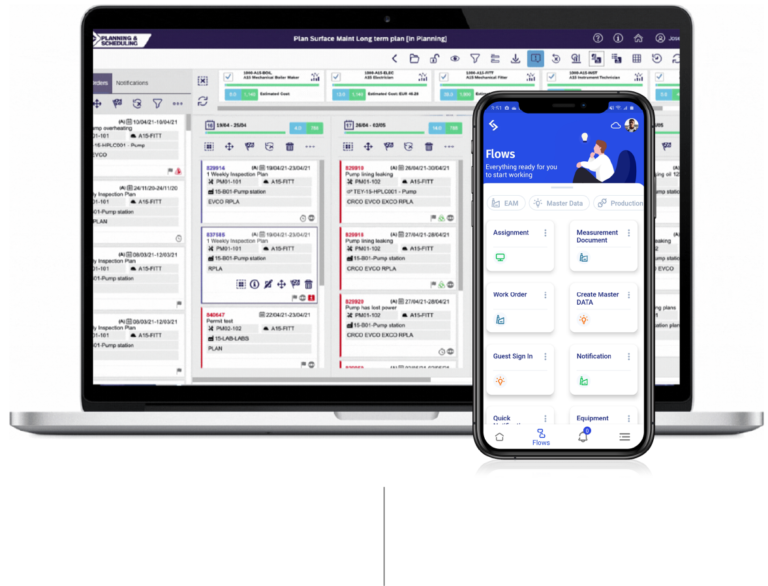

Replace paper processes to connect the workforce

According to the NIST Manufacturing Cost Guide, maintenance costs average 2.7% of sales. This doesn’t take into consideration production labor costs, delays, and the cost of defects due to poor asset maintenance. Overcome challenges driven by excessive unplanned downtime through optimizing maintenance work management. Replace paper and excessive administrative tasks through mobile apps and software that connect front end workers with SAP. Results include increased wrench time, cost savings, and improved OEE.

Sigga enables manufacturers to:

Increase OEE

Reduce unplanned downtime

Reduce MTTR

Increase technician productivity

Increase MTBF

Adherence to PM schedule

Improve Collaboration

Real-time visibility in SAP to resources and work status

Increase Staff Productivity

Reduce data entry and time wastes

Increase Compliance

Complete and documented safety inspections

Customer Success

Manufacturing organizations who use Sigga for end-to-end digital work management, experience, on average:

Maintenance Costs

15%

Reduction

Wrench Time

25%

Increase

Administrative Work

20%

Decrease

Manufacturing Transformation Across Global Sites: An Interview with Saint Gobain

The IT Project Lead at the largest building materials company in the world, talks about going from paper to fully digital maintenance processes in their global glass factories.

Effective resolutions for operational challenges

Sigga understands your challenges and can guide you through a digital transformation across maintenance operations. More than 70,000 technicians across the globe use Sigga mobile maintenance app every day. And some of the world’s largest food & beverage organizations rely on Sigga Planning & Scheduling. Investing in digital maintenance tools now will help keep your organization profitable and competitive long-term.