The leap from Industry 4.0 to Industry 5.0

November 10, 2020It seems that when we were finally understanding, implementing, and getting used to Industry 4.0, the term 5.0 came about. When did this happen? Why so fast?

We may even think: “I’m not even finished adapting to Industry 4.0! Does this mean that I have to start from scratch all over again? So soon?”

The answer is no.

There is no need to discard or forget Industry 4.0 to be a part of Industry 5.0 This happens because Industry 4.0 and Industry 5.0 are mutually complementary, not mutually exclusive.

In this article, we’ll open the conversation toward understanding the relationship between Industry 4.0 and 5.0 and its importance for business and society.

Regardless of our industry or line of work, we’re currently experiencing historically high rates of change. These changes have become part of everyone’s everyday life.

Industry 4.0 brought advances that allowed intelligent machines and other technological equipment to do much of the work in factories and production facilities.

However, between March and April 2020, entire production chains all over the world came to a standstill due to the COVID-19 pandemic.

If the disease only affects humans, why didn’t the machines continue to do their job?

This moment helped us reflect on the role and importance of humans in the job market. We realized that even though machinery and equipment can operationalize tasks, all industries still need people.

As most of the planet went through this process in early 2020, Japan had gone through a similar process several years ago.

This situation led the government to question existing technological advancements and move from “What is disrupting our way of life today?” to “What will disrupt our way of life tomorrow?” The recognition of the need to think ahead is what brought Industry 5.0

Industry 5.0 is the future and already an emerging trend: the interaction and collaboration between man and machine. This cyber-physical systems revolution that was summarized in Industry 4.0 has evolved into Industry 5.0 and is fundamentally changing the way we live, work, and relate to one another.

This next wave of the industrial revolution needs to define how we collaborate and how we define the rules between human and machine interaction.

The levels of collaboration between people and machines will change given that most automation, machine intelligence, and even robots are working in the background to support the workforce or taking on large portions of production and manufacturing tasks and processes.

Business leaders can no longer focus on developments and trends in their sectors alone but need to understand potential transformations and disruptions in the entire world of suppliers, customers, and global markets.

The rapid pace of change is challenging the entire workforce, governments, legislators, and regulators to an unprecedented degree.

The world of the work-life merge, the term coined by Facebook executive Emily White in 2012, describes a life in which work and free time are no longer neatly compartmentalized but seamlessly jumbled up together. As most will know, this jumbling has been accelerated due to COVID-19.

At the same time, there is a risk that parts of society might feel left out due to the perception that jobs are being taken away by automation and immigration or because they lack the skills required for the newly created jobs.

However, Industry 5.0 has not kept people from getting jobs. If anything, Industry 5.0 brought about the importance of including human beings in the process.

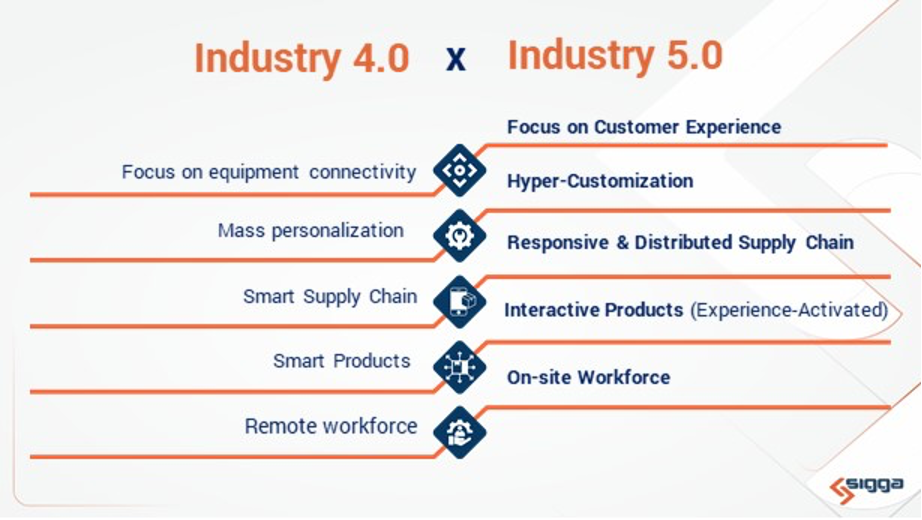

The infographic below illustrates this paradigm shift:

Perhaps the greatest learning from the 4.0 era was the understanding that technology alone does nothing.

Machines depend on operators, programmers, and maintenance. Not everything can be automated.

Additionally, we know that our human cognitive power and analytical capabilities remain irreplaceable.

Industries work by transforming resources into goods, but the most valuable and irreplaceable resource in any industry is the people that work in it and uses its products.

Industry 5.0’s focus is on creating value beyond financial results. Industry 5.0 seeks to improve the quality of life, not only for people involved in industrial processes but for society as a whole.

Until a few years ago, Industry 4.0 was the latest thing, but, as we know, the world changes quickly, and the 4th Industrial Revolution evolved into a new concept.

Does this mean that everything you’ve learned and applied from Industry 4.0 has already become obsolete?

No. Let’s discuss why.

The main idea of Industry 5.0 is to use the technology developed in Industry 4.0 and bring its benefits to human beings.

It’s also worth noting that, in some places, implementing Industry 4.0 is still a challenge and that it may seem that getting to Industry 5.0 can take years or mixed in with intense cultural transformation. But it must be considered as soon as possible.

When thinking about the path to Industry 5.0, it may seem that we first have to go through Industry 2.0, 3.0, and, 4.0, but this is not the case. This process is not a ladder.

Although not all stages of production can join Industry 5.0 right away, this should not stop you from implementing what is possible with your existing processes. Remember, no matter where you are in your technological journey, Industry 5.0 does not replace what you already have.

As much as Industry 4.0 has brought us great technological advances, Industry 5.0 shows us that technology, by itself, is not the answer to everything.

With people at the center of processes, Industry 5.0 focuses on three increasingly important aspects: quality of life, inclusion, and sustainability.

- Industry 5.0 aims to make workers’ lives safer and more comfortable while ensuring access to technologies that enable automation and increase productivity.

- Industry 5.0’s human approach to technology emphasizes the contributions of the individual while creating a more inclusive space in the labor market, as well as in the access o products and services.

- Industry 5.0 helps people understand that technology is an essential tool for developing and engaging in sustainable practices by caring for the environment, protecting the world’s ecosystems, and making the best use of available resources for current and future generations.

Take a moment to look around and notice how these aspects have become everyday topics and have promoted a profound change in our approach to business, production, and our way of living.

Does it seem challenging for you and your business to adapt?

You’re not alone.

Here at Sigga, part of our mission is to help our customers to embrace, adapt, and overcome these challenges. Our solutions can help you reach Industry 5.0 through a human approach to cutting-edge technology.

Sigga‘s 20+ years of experience in SAP integration, asset management, and industrial maintenance solutions can efficiently guide you and your company through the process. You can partner with a company trusted by global industry giants such as ABInbev, Bunge, Danone, Petrobras, and Saint-Gobain.

Sigga’s solutions allow you to optimize your data flow, execute maintenance routines, eliminate unproductive tasks, and excessive unnecessary shifts, and reduce paper usage to zero.

Using Sigga’s EAM Product Suite greatly facilitates executing your asset management strategy objectives as well as reaching your asset performance and productivity goals.

Enable your company’s digital transformation. Learn more about Sigga’s Solutions portfolio.